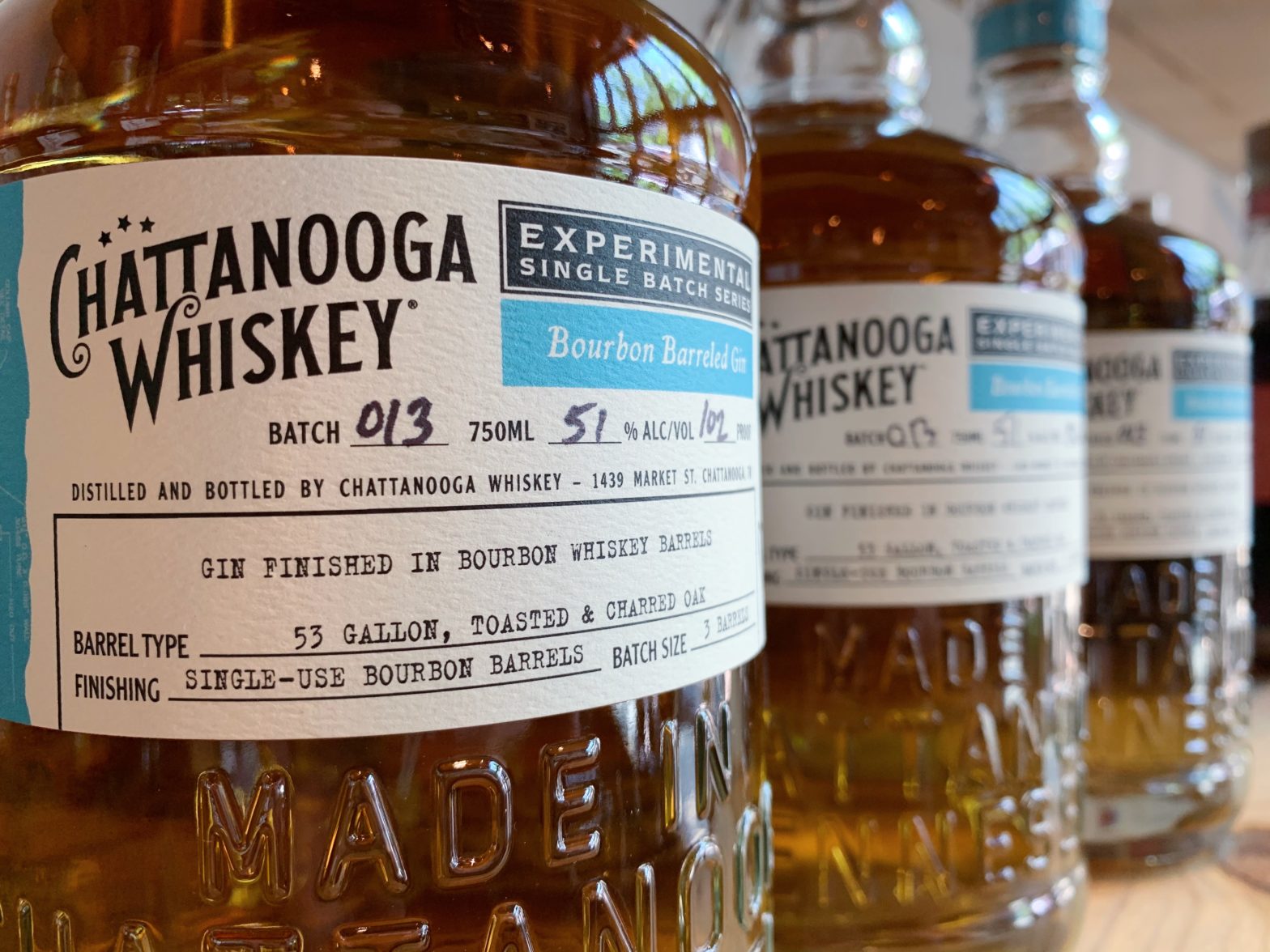

Inside the Experimentation Process: Batch 013

Our Experimental Single Batch Series is something of a playground for our distillers. A limited collection of single-batch spirits born from our 100-gallon pot column still at our Experimental Distillery in downtown Chattanooga, this series seeks to express uncompromised creativity and innovation within our craft. Some experiments test individual ingredients, while others test completely unique concepts from start to finish.

In the case of our most recent experiment, Batch 013, the concept was simple: our distillers wanted to make a barrel aged gin. And while that may sound simple enough, the process of developing a gin recipe became one of our most complex experiments to date. After nearly 12 months of research and testing, Batch 013 was born.

Before the release, we sat down with two of our distillers, Grant McCracken and Tiana Saul, to ask them about the process of creating their first gin.

Step 1: Style Selection

Tiana: What makes gin interesting is that the requirements for gin are very simple. Namely, spirits with a main characteristic flavor derived from juniper berries. That leaves a lot of room for experimentation and interpretation.

Grant: Rather than make a light and crisp London style gin, we honed in on the Genever style. Genever gin is basically a malty, more flavorful precursor to gin, and really spoke to our style. It’s definitely the “whiskiest” gin style.

Step 2: Ingredient Selection

G: Most gin is redistilled with a flavorless neutral spirit. Our gin, on the other hand, uses our Tennessee High Malt white whiskey as the base spirit.

T: Since we would be using our own Tennessee High Malt white whiskey as the base, we wanted to select botanicals that could complement and balance the malty, fruity, sweet character of the new make. After the required juniper, we chose a few classic botanicals like coriander, lemon peel, and orris root, but also opted to test out a few wildcards to give it our own twist.

Step 3: Single Botanical Testing

T: Since botanical distillation was pretty much new territory for all of us, we opted to take the time to individually distill each ingredient on a table top lab still to try and get a better idea of how they each expressed themselves. That way, when coming up with a final blend, we could have a more educated idea of how each flavor and aroma would translate to the final product.

G: Each ingredient has its own unique flavor and aromatic characteristics. When distilled independently, you can isolate those individual characteristics. Juniper might smell a certain way out of the bag, and a certain way on its own, but what does it smell and taste like with other botanicals?

Step 4: Bringing the Botanicals Together

G: Once a rough recipe was decided, we began testing the ingredients together in a 10-liter pot still. We tested everything: ingredient ratios, steep times, and still proofs, all over and over again, creating dozens of different recipes to choose from.

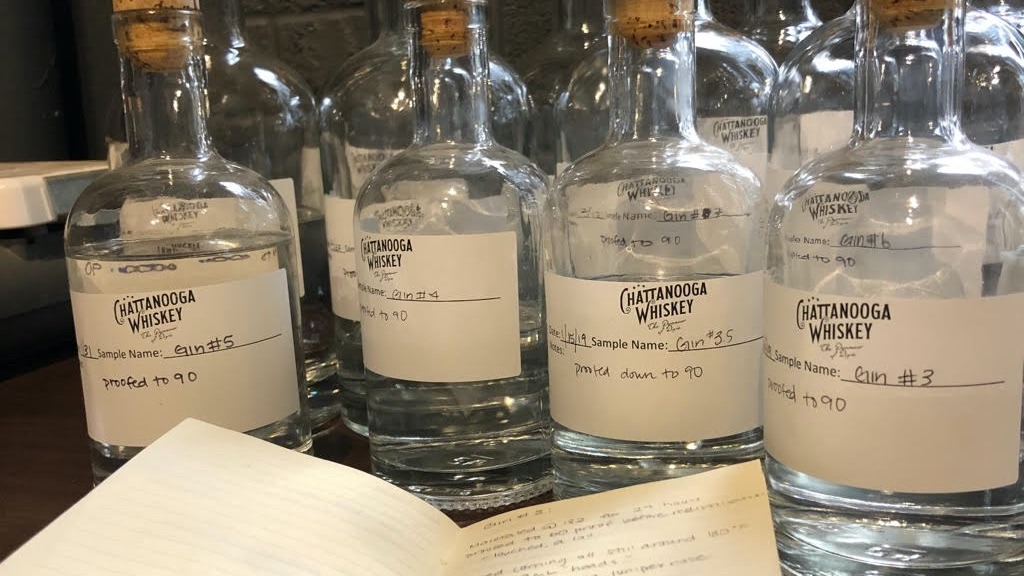

Step 5: Recipe Selection

G: We blind-tasted all of the samples to determine what recipes stood out from the rest. There were definitely personal preferences, but one particular recipe became the favorite.

T: Although we were making a gin, the core foundation of our company is built on whiskey, so we didn’t want to veer too far from our roots. While we wanted to highlight the top notes that make gin bright and refreshing, we also wanted to keep the earthy sweetness characteristic of our Tennessee High Malt. To accomplish that, we experimented with steeping one of our flagship malts in the distillate with the other botanicals, and we ended up being quite pleased with the results.

Step 6: Scale Up to 100 Gallon Distillations

T: One of the biggest challenges in this project came with the realization that scaling up did not necessarily result in a one to one increase. The proportions and processes at 1 liter did not always translate to 100 gallons. Luckily, we are able to make adjustments on the fly to get the profile we wanted, but it did require continuous tasting off the still… at 9am… at 150+ proof…

Step 7: Finishing

G: Although we appreciated the light, clean character of a classic gin, we remembered that we were whiskey makers! So we decided to barrel age our gin in our single-use Tennessee High Malt barrels. After 8 months, the gin had a chance to oxidize, allowing the sweet character from the barrel to give the gin a softer approach and a richer, fuller character.

Step 8: Proofing and Bottling

T: Once the recipe was finalized, the product distilled, and the barrels filled, and we thought we were finally done with the development of the gin, we realized we had not taken into account how differently the product showed at various proofs. We had to go back to bench blending and blind tasting in order to choose which proof expressed both the aroma and palate we were looking for.

G: Every time you add a little water to the gin, different aromatic compounds are volatilized. It was amazing to smell and taste how different bottling proofs expressed certain botanicals over others.

Step 9: Whiskey-lover’s Gin

T: I love whiskey, but gin was definitely my first obsession. This project not only checked off the “Make a Gin” line on my personal bucket list, but it was also a great lesson in experimentation and the trials and tribulations of R&D. We were forced to start from scratch, break everything down, and teach ourselves as we went along. We learned a lot, failed a lot, and drank a lot… and we’re pretty pleased with the results.

G: We started this project nearly 20 months ago with the goal of making a gin for whiskey-lovers… or maybe we wanted to make a whiskey for gin-lovers… I can’t remember now. It’s awesome either way!

Step 10: Cheers!

T: This is a gin, there’s no doubting that, but with the Tennessee High Malt base and the malty-sweet, barrel-aged body, it does bridge a gap between gin and whiskey. With that in mind, try using it in a classic cocktail of either spirit. Enhance the citrus notes by using it in a Tom Collins, or enjoy the whiskey-like richness by substituting it in your favorite Old Fashioned recipe.